When choosing a CNC lathe, careful consideration should be given to the compatibility of tools and accessories.ģ. The random accessories, accessories and their supply capacity and tools of CNC lathes are very critical to the CNC lathes and turning management centers that have been put into production. Purchase of machine tool accessories and tools Generally, the more users, the higher the reliability of the CNC system.Ģ. Select CNC lathes with reasonable structure, sophisticated production and mass production. That is, the average failure-free time is long, even if a common failure occurs, it can be recovered in a short time and put into use again. The reliability of the CNC lathe is that when the index-controlled lathe performs its function under the specified standards, it runs stably for a long time without common failures. Choose according to reliability, which is the guarantee of improving product quality and production efficiency.

According to the precision requirements, that is, the dimensional accuracy, positioning accuracy and surface roughness of the workpiece, the control accuracy of the CNC lathe is selected. The process requirements of typical parts are mainly the structural size, production and processing range and precision requirements of the parts. It has been widely valued by countries all over the world for decades and has suffered a rapid development trend.ĭetermine the process requirements of typical parts and the large quantities of workpieces produced and processed, and the function of formulating CNC lathes is to make early preparations, and the prerequisites for rational use of CNC lathes to meet the process requirements of typical parts It occupies a very critical position in CNC lathes. CNC lathe is one of the main types of CNC lathes. The technical level of CNC lathes and the percentage of CNC lathe production and total ownership in metal cutting production and processing are one of the key indicators to measure the development trend of a country’s national economy and the overall level of industrial manufacturing. It is a working mother machine with the advantages of high precision, high efficiency, high automation and high flexible production in mechanical manufacturing equipment. CNC lathe is a mechatronics product that integrates mechanical, electrical, hydraulic, pneumatic, microelectronics and information content. The rational use of CNC lathes should follow the following principles:ĬNC lathes, also known as CNC machining center lathes, namely computer-controlled lathes, are currently the most widely used CNC lathes in China, accounting for about 25% of the total number of CNC lathes.

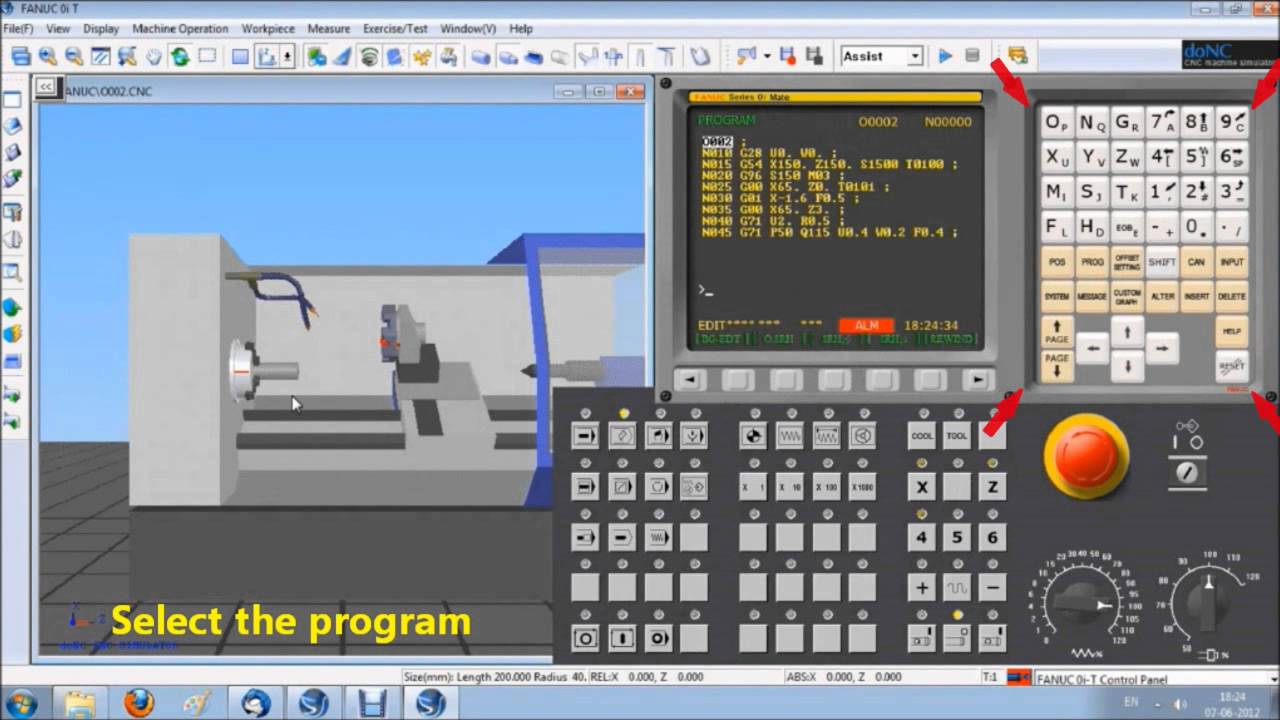

LATHE CNC SIMULATOR FULL

It has various compensation functions for parallel line milling and circular arc milling, and gives full play to good economic and practical effects in the mass production of complex parts. It has a wide range of processing capabilities and can produce and process parallel cylinders, oblique cylinders, arcs and various threads. CNC lathe, turning management center, is a high-precision, high-efficiency automatic CNC lathe.

0 kommentar(er)

0 kommentar(er)